Our expertise

Why numerical simulation?

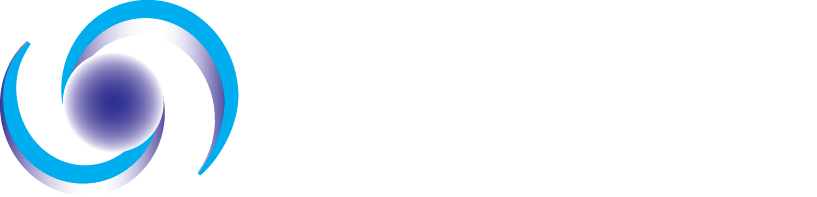

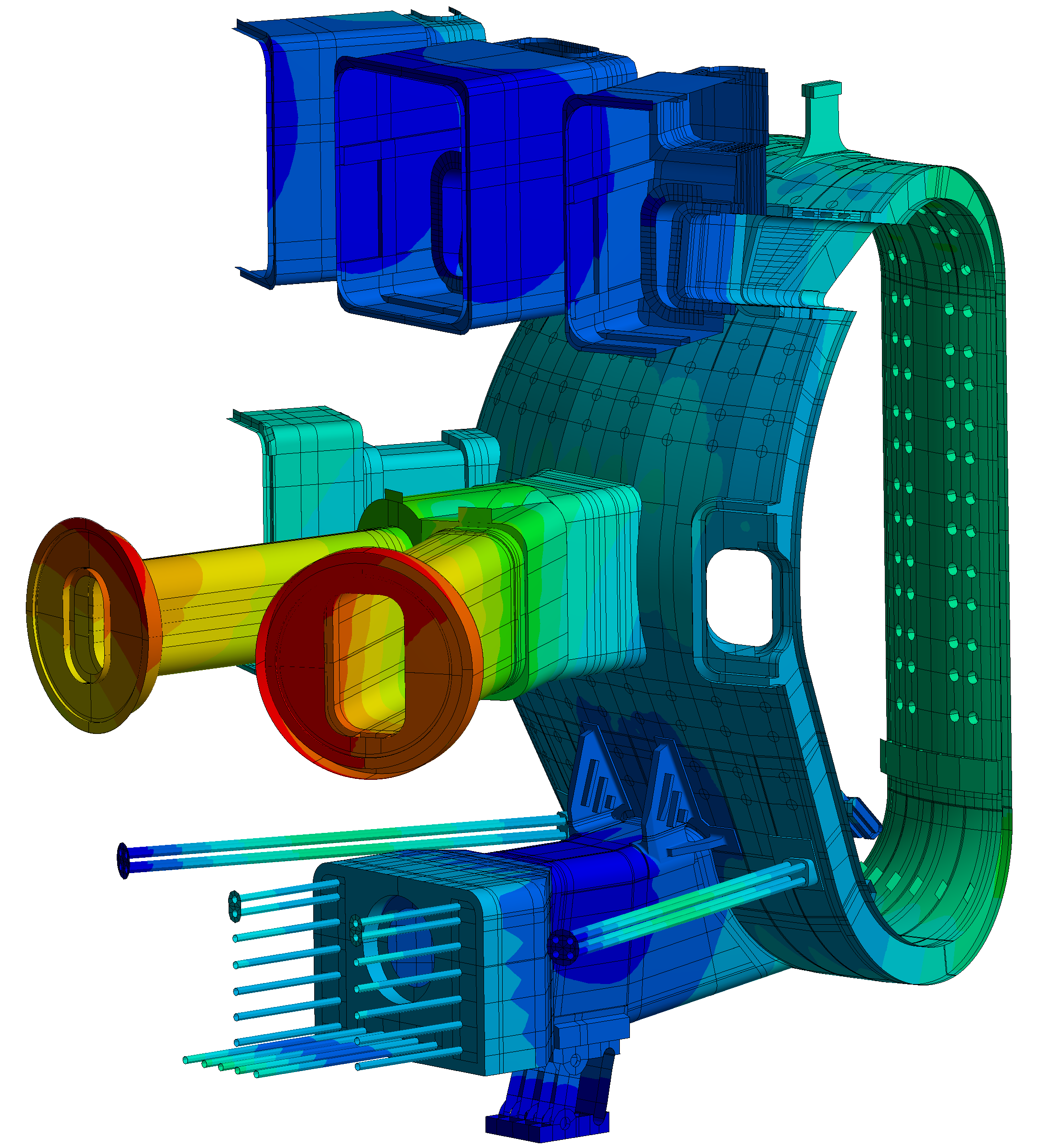

Our expertise in numerical simulation allows us to predict by calculation the physical behavior of a given system. Hence, it reduces the costs of developing innovative products or processes by minimizing the prototyping or experimental phases, which are often complex to carry on. Furthermore, numerical simulation is also an essential tool for the industrial optimization of products or processes; reducing manufacturing costs by saving materials, improving performance, increasing reliability and robustness. Numerical simulation is thusly a major asset of design assistance for the engineer when sizing a system.

Many methodologies can be used to provide an adequate response to a given problem: For example, the “Best Estimate” approach consists of creating a digital twin whose response to a request is the closest to reality.Furthermore, in the nuclear industry, this method is also associated with uncertainty propagation calculations to exploit the results (in particular for safety studies). For the so-called “conservative” approaches, the calculation assumptions are adjusted in order to guard against the uncertainties intrinsically linked to the calculations. Therefore, these conservations are chosen in a sufficient broadway and make it possible to ensure that the consequences calculated are much greater than the real consequences in the event of an accident.

The Numerical Steps

Pre-processing:

Definition of the geometry, mesh, definition of the calculations hypotheses, boundary conditions, solver settings

Processing:

Solving matrix systems by the calculation code, controlling the calculation convergence.

Post-processing:

Visualization, exploitation and results analysis